Описание

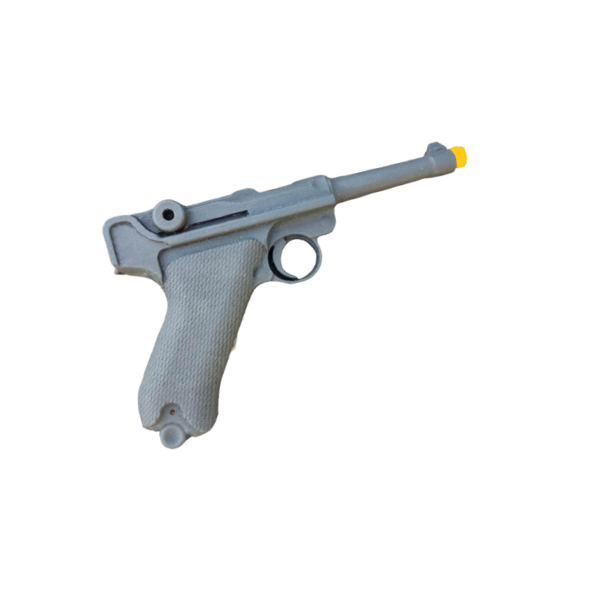

Parabellum Luger P08 Pistol WWII wooden handmade copy. The wooden pistol is made entirely of wood at a scale of 1:1, Has a high degree of detail.

It can be used as a model for role-playing games in reconstructions and military holidays. Excellent quality for a low price. Boys who love military adventures will get special joy.

Can decorate your amateur or professional museum of military glory.

This toy has no internal mechanisms and can never cause injury or harm to health.

Outside painted with durable safety paint.

The main advantages of the Parabellum Luger P08 Pistol WWII wooden handmade copy:

1. There are no analogues. An exclusive toy, each copy is a handmade product.

2. Made from environmentally friendly wood.

3. Quiet model.

4. Durability.

5. Ideal price for this level of quality.

Give your child or loved one a rare, exclusive gift!

You can also look at the Browning Automatic Rifle M1918 BAR.

You can see a video about this model on my YouTube channel. Feel free to like and follow it so others can find me. And of course, don’t forget about Facebook. Thanks if you do this.

From Wikipedia: The main advantage of the Parabellum is its high shooting accuracy , achieved due to a comfortable anatomical handle with a large angle of inclination and easy release. It combined high power with sufficient compactness compared to other military pistols at the beginning of the 20th century .

Complex and expensive to manufacture, the Parabellum nevertheless proved to be very successful and became an advanced weapon system for its time.

In the production of Luger pistols, alloy steel was used, which has increased strength and corrosion resistance. The main parts of the weapon, such as the frame, barrel, bolt, and others, were subjected to conventional heat treatment by hardening to the required hardness. At the same time, various parts were hardened to the strength they required. The parts of the trigger mechanism and the connecting axes underwent heat treatment using the method of carburization (carburization), that is, diffusion saturation of the surface layer of steel with carbon when heated in a carburizing environment. Parts processed in this way acquire their final properties after hardening and low tempering. The purpose of this treatment is to impart high hardness and wear resistance to the surface layer, increase the limit of contact endurance and the limit of bending endurance while maintaining a sufficiently viscous core – the main body of the part. The thickness of the carburized layer did not exceed one millimeter. As a result, these parts had both strength and the necessary ductility, which allowed them to constantly withstand the heaviest loads.

I am always happy to accept individual orders of any complexity. The main thing is that they are interesting to work with. You can always ask me about it.

Отзывы

Отзывов пока нет.